GMS-FTRSTEEL BALL MILL PROCESS OPTIMISATION

GMS-FTRSTEEL BALL MILL PROCESS OPTIMISATION

GMS-FTRSTEEL's team of experts recently conducted a comprehensive process study for four ball mills within a plant operated by one of the world's largest cement groups. These ball mills, all situated in the same plant, operate within a closed-circuit process, with a focus on addressing energy consumption and achieving desired fineness levels as per the customer's requirements.

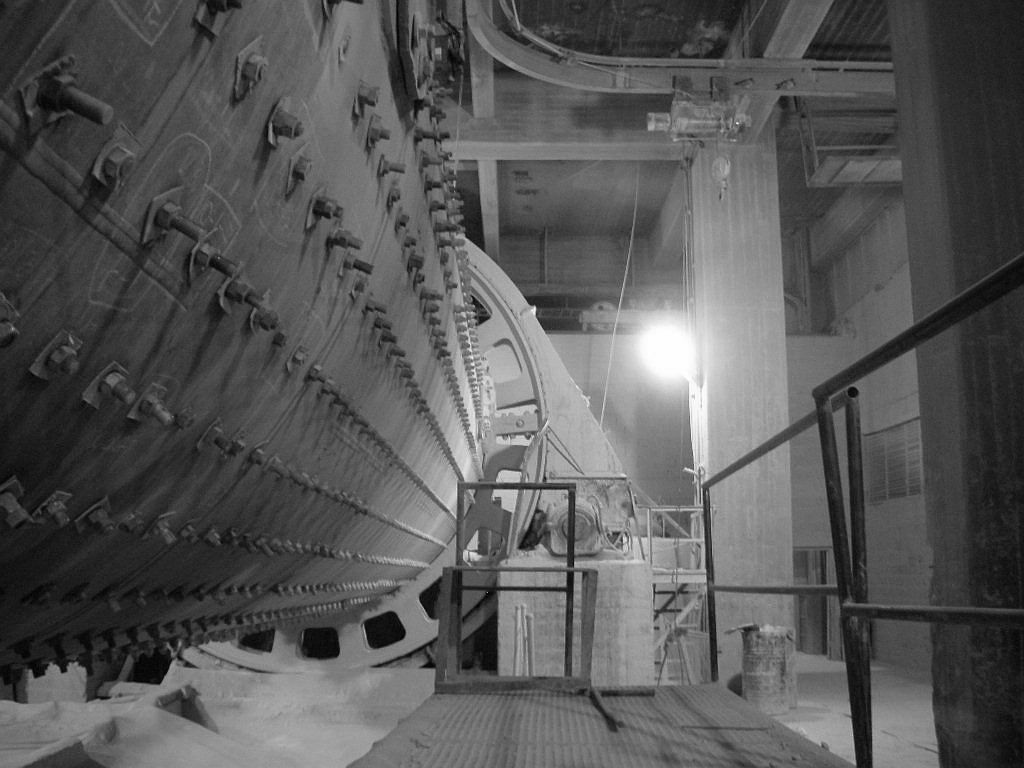

Following meticulous analysis and testing, detailed reports were compiled. Subsequently, two of the mills were outfitted with GMS-FTRSTEEL's complete shell liners for both the 1st and 2nd chambers, along with intermediate and outlet diaphragms. Additionally, new optimal ball charges were introduced within the mills. As a result, these mills are now primed for enhanced performance and efficiency.

The remaining two mills are scheduled for similar upgrades within the next six months, ensuring uniformity and optimization across the entire plant.

GMS-FTRSTEEL's commitment to customer satisfaction extends beyond the initial implementation. Our experts remain on-site to conduct audits of grinding circuits, offering tailored, cost-effective solutions. This includes providing all necessary castings and equipment to ensure optimal performance and longevity of the grinding process.